Advanced Control Systems for Wind Turbines Explained

Category: Renewable Energy

Discover How Advanced Control Systems Optimize Wind Turbines

Whether you're an electrical engineer diving deeper into renewable energy innovations or a curious beginner wanting to understand the science behind wind power, mastering advanced control systems for wind turbines is essential. These systems are the brain behind every turbine's efficiency, reliability, and adaptability in harnessing wind energy. If you've landed here, you're likely searching for clear, in-depth insights that go beyond the basics, aiming to understand how cutting-edge control strategies improve turbine performance amidst fluctuating wind conditions and grid demands. Traditional control methods can only do so much; advanced systems leverage adaptive, predictive, and fault-tolerant technologies to maximize output while safeguarding expensive equipment. This post fills the gap left by overly technical papers and lightweight overviews by breaking down complex concepts into accessible sections, backed by the latest innovations and practical examples. From pitch and yaw controls to modern model predictive control and SCADA integrations, we'll explore it all in a structured way that helps you grasp underlying principles and practical applications. Read on to level up your knowledge of wind turbine control systems, empowering you to contribute meaningfully to the renewable energy transition or optimize your engineering projects with confidence.

- Discover How Advanced Control Systems Optimize Wind Turbines

- Overview of Wind Turbine Control Systems

- Basic Control Mechanisms in Wind Turbines

- Advanced Control Strategies for Wind Turbines

- Model Predictive Control (MPC) for Wind Turbines

- Fault Detection and Fault-Tolerant Control in Wind Turbines

- Integration with SCADA and IoT: Enhancing Wind Turbine Control with Real-Time Monitoring and Smart Grid Communication

- Multi-Turbine Control and Wind Farm Optimization: Coordinated Approaches for Maximizing Output and Minimizing Wake Losses

- Emerging Technologies and Research Trends in Wind Turbine Control Systems

- Practical Challenges and Implementation Considerations in Advanced Wind Turbine Control Systems

- Future Outlook and Impact on Renewable Energy

Overview of Wind Turbine Control Systems

Understanding the fundamental concepts of wind turbine control systems is crucial for optimizing energy capture and ensuring structural safety. At their core, control systems regulate the turbine’s rotor speed, blade pitch, generator torque, and yaw orientation to adapt to constantly changing wind conditions. These systems balance competing goals: maximizing power output when winds are moderate and protecting turbine components from damage during high winds or faults. Without sophisticated control strategies, turbines risk either underperforming or sustaining costly mechanical failures.

Control systems for wind turbines are broadly classified into two types: active and passive controls. Passive control systems rely on fixed mechanical properties or simple aerodynamic designs to modulate performance with minimal real-time adjustment. For example, a fixed-pitch blade that naturally stalls at high wind speeds is a passive safety measure. In contrast, active control systems continuously monitor environmental and turbine parameters via sensors and dynamically adjust components like blade pitch angle and generator torque. This adaptability enables turbines to operate efficiently across a wider range of wind speeds and grid demands.

Despite these advancements, challenges in wind energy conversion persist, including turbulent wind fluctuations, complex aerodynamic interactions, and the need for rapid fault detection and response. Control systems must navigate these challenges while maintaining grid stability and complying with increasingly stringent operational standards. As wind farms grow larger and more interconnected, advanced control algorithms employing model predictive control, machine learning, and adaptive filtering are key to unlocking higher performance and reliability in modern wind turbines.

Image courtesy of Duc Nguyen

Basic Control Mechanisms in Wind Turbines

To grasp the foundation of wind turbine control, it’s essential to understand the three primary basic control mechanisms traditionally used: pitch control, generator torque control, and yaw control. Each plays a distinct role in maximizing energy capture while maintaining the turbine's structural integrity and operational safety.

1. Pitch Control

Pitch control involves adjusting the blades' angle relative to the wind to regulate rotor speed and aerodynamic forces. At lower wind speeds, blades are pitched to maximize lift and capture more energy. As wind speeds increase towards rated levels, pitch angles are fine-tuned to maintain optimal rotor speed and prevent mechanical overload. During extremely high winds, blades are pitched out of the wind ("feathered") to minimize stress and avoid damage. This dynamic blade adjustment is critical for both performance and protection but is limited by mechanical response times and actuator wear, especially under turbulent conditions.

2. Generator Torque Control

Generator torque control directly regulates the electrical torque output of the generator to maintain optimal rotor speed and maximize power extraction, particularly below rated wind speeds. By adjusting the electromagnetic torque, the control system ensures that the rotor accelerates or decelerates appropriately to match wind power input fluctuations. This mechanism is often implemented through power electronics and converter systems, enabling precise control over torque applied to the grid. However, traditional generator torque control may struggle with rapid wind gusts or transient grid disturbances, making it less responsive without integration with other control loops.

3. Yaw Control

Yaw control aligns the turbine rotor with the prevailing wind direction to maximize aerodynamic efficiency. It involves rotating the entire nacelle horizontally to face the wind, using yaw motors and sensors that monitor wind direction changes. Accurate yawing reduces aerodynamic losses and increases energy capture by ensuring wind hits blades at the optimal angle. Nevertheless, yaw control is constrained by mechanical wear from frequent adjustments and latency in detecting sustained wind direction shifts, which could temporarily reduce efficiency if misalignment occurs.

Together, these basic control mechanisms form the backbone of traditional wind turbine operation. While effective for standard conditions, their limitations include slower response to complex wind dynamics, mechanical fatigue from continuous adjustments, and challenges in integrating with grid demands. This paves the way for advanced control algorithms that enhance and coordinate these mechanisms to push turbine performance beyond conventional boundaries.

Image courtesy of Egor Kunovsky

Advanced Control Strategies for Wind Turbines

As wind conditions become increasingly variable and unpredictable, traditional control methods face limitations in maintaining optimal turbine performance and structural safety. This has driven the development of advanced control strategies that go beyond fixed-rule adjustments, enabling wind turbines to respond dynamically and intelligently to fluctuating environments. Among the most promising approaches are adaptive control, fuzzy logic control, and neural network-based control systems. These methods incorporate real-time learning, uncertainty handling, and nonlinear system modeling to enhance power output, prolong equipment life, and reduce downtime.

1. Adaptive Control

Adaptive control mechanisms continuously update control parameters based on real-time feedback from the turbine and its environment. Unlike fixed-parameter controllers, adaptive systems adjust to changes in wind speed, turbulence intensity, and mechanical wear, ensuring consistent performance across various operating conditions. For example, adaptive pitch control algorithms can refine blade angles on the fly, optimizing aerodynamic efficiency during gusts while minimizing mechanical stress. This dynamic tuning improves robustness and fault tolerance, making adaptive control essential for modern turbines operating in diverse wind regimes.

2. Fuzzy Logic Control

Fuzzy logic control introduces a sophisticated way to handle ambiguous or imprecise input data, which are common in wind measurements and turbine responses. By using linguistic rules and membership functions rather than exact numerical models, fuzzy controllers mimic human reasoning to make control decisions in complex, nonlinear scenarios. This makes them highly effective in managing the uncertainties of turbulent wind flow, sudden gusts, or sensor inaccuracies. Fuzzy logic enables smoother transitions in control actions such as pitching and torque regulation, often resulting in improved energy capture and reduced mechanical fatigue compared to traditional binary or linear controllers.

3. Neural Network-Based Control Systems

Leveraging advances in artificial intelligence, neural network-based control systems learn the intricate relationships between wind patterns, turbine dynamics, and power output through training on historical and sensor data. These systems excel at modeling the nonlinear and time-varying characteristics of wind turbine operation without relying on explicit analytical models. Neural networks can predict optimal control inputs—like blade pitch angles and generator torque—to maximize efficiency while maintaining structural integrity. Furthermore, neural control architectures often integrate predictive capabilities, enabling turbines to anticipate changes in wind conditions and adapt preemptively, which significantly enhances stability and grid compliance.

Together, these advanced control strategies represent the frontier of wind turbine optimization, enabling machines to intelligently adapt to highly variable and uncertain wind environments. By adopting adaptive control, fuzzy logic, and neural network methodologies, engineers can dramatically improve turbine responsiveness, resilience, and energy output—key factors in advancing the global renewable energy transition.

Image courtesy of Pixabay

Model Predictive Control (MPC) for Wind Turbines

Among advanced control strategies, Model Predictive Control (MPC) stands out as a powerful approach that anticipates future wind conditions to optimize turbine performance and minimize mechanical stress. Unlike reactive controls that adjust turbine parameters based only on current measurements, MPC uses a dynamic model of the wind turbine and forecasts of wind speed and direction to calculate the optimal control actions over a future time horizon. This predictive capability allows turbines to proactively manage rotor speed, blade pitch, and generator torque, effectively balancing energy capture and structural load reduction amidst fluctuating wind patterns.

The core strength of MPC lies in its ability to solve an optimization problem at each control interval, considering system constraints such as actuator limits and mechanical fatigue thresholds. It evaluates multiple possible control trajectories, selecting the one that maximizes power output while minimizing stresses on blades and drivetrain components. This results in smoother control inputs and improved durability of turbine parts. Real-world implementations often integrate MPC with sensor data and wind forecasts, enabling turbines to anticipate gusts and adjust control parameters before abrupt wind changes occur.

Example Algorithms and Real-World Applications

- Linear MPC (LMPC) applies simplified linear models to predict wind turbine behavior and compute efficient control moves in real time. LMPC is popular due to its relatively low computational demand and good performance in moderate wind regimes.

- Nonlinear MPC (NMPC) tackles the inherently nonlinear aerodynamics and mechanical dynamics of turbines for higher-fidelity control but requires more computing power and sophisticated solvers.

- Robust MPC incorporates uncertainty in wind forecasts and model inaccuracies to maintain turbine performance under unpredictable conditions.

Several commercial wind turbine manufacturers and research institutions are adopting MPC to enhance turbine lifespan and energy capture. For example, large offshore wind projects benefit from MPC algorithms that reduce mechanical loads caused by turbulent seas and shifting weather patterns. Moreover, grid operators increasingly favor MPC-controlled turbines for their ability to provide predictable and stable power output, aiding grid reliability.

By incorporating Model Predictive Control, wind turbines can transform from reactive machines into intelligent systems that strategically respond to changing environments—significantly improving efficiency, reducing maintenance costs, and advancing the renewable energy landscape.

Image courtesy of Artem Podrez

Fault Detection and Fault-Tolerant Control in Wind Turbines

Ensuring continuous and safe operation of wind turbines requires sophisticated fault detection and fault-tolerant control techniques that identify and mitigate sensor and actuator failures before they escalate into costly breakdowns or shutdowns. Modern wind turbines rely on a myriad of sensors—monitoring wind speed, blade position, temperature, vibration, and electrical parameters—and actuators responsible for pitch, yaw, and generator torque control. Faults in any of these components can lead to inaccurate data, control errors, and mechanical stress, thereby reducing turbine efficiency or triggering unwanted downtimes.

Techniques for Fault Detection

Effective fault diagnosis involves real-time monitoring and analysis of sensor and actuator signals to detect anomalies that deviate from expected turbine behavior. Common fault detection methods include:

-

Model-based Approaches: These use mathematical models of the turbine’s normal operation to generate expected outputs, which are compared against actual sensor readings. Significant discrepancies indicate potential faults. Residual generation and thresholding techniques help isolate faults in pitch actuators, yaw motors, or sensors.

-

Signal Processing and Statistical Methods: Techniques such as wavelet transform, Principal Component Analysis (PCA), and Kalman filtering analyze vibration patterns, electrical signals, and sensor noise to identify early signs of faults or degradation.

-

Machine Learning Algorithms: Leveraging historical fault data, machine learning models—such as support vector machines or neural networks—classify and predict faults based on complex multi-sensor inputs, providing robust fault detection even under ambiguous conditions.

Fault-Tolerant Control Strategies

Once a fault is detected, fault-tolerant control (FTC) systems aim to maintain turbine operation with minimal performance loss by compensating for faulty components or switching to safe operating modes. Key FTC techniques include:

- Reconfigurable Control: Dynamically adjusts control parameters or replaces faulty sensor data with estimations from observers or redundant sensors, ensuring continued accurate control of blade pitch and generator torque.

- Passive Fault Tolerance: Designs that inherently withstand certain faults without active intervention, such as redundant actuators or fail-safe mechanical components.

- Fault Accommodation: When faults are unavoidable, control strategies gracefully degrade turbine operation to safe levels, preventing damage while maintaining grid compliance.

Integrating fault detection with fault-tolerant control not only improves turbine reliability and availability but also reduces maintenance costs and extends equipment life. As wind farms scale and deploy in harsher environments, advanced fault diagnosis and robust FTC frameworks become vital components in maximizing wind energy harvest and ensuring resilient renewable power generation.

Image courtesy of Aleksey Kuprikov

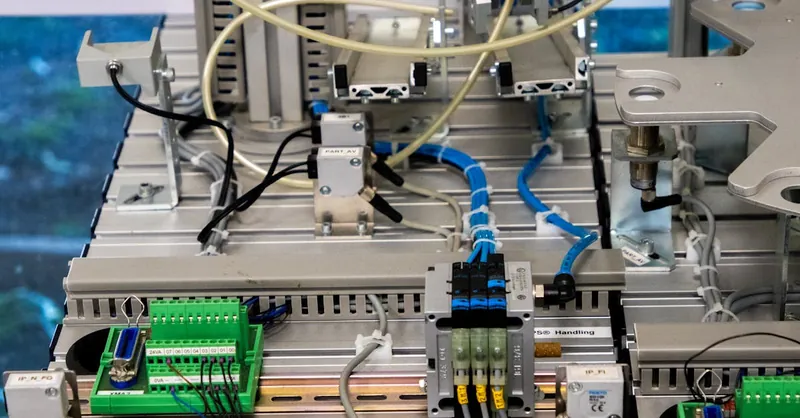

Integration with SCADA and IoT: Enhancing Wind Turbine Control with Real-Time Monitoring and Smart Grid Communication

Modern wind turbine control systems increasingly rely on Supervisory Control and Data Acquisition (SCADA) and Internet of Things (IoT) technologies to achieve superior operational efficiency, predictive maintenance, and seamless grid integration. SCADA systems serve as the central nervous system, gathering real-time data from multiple sensors distributed across the turbine and wind farm. This enables operators and control algorithms to monitor critical parameters such as rotor speed, blade pitch angles, yaw position, vibration levels, and electrical output continuously. The real power of SCADA lies in its ability to aggregate vast amounts of sensor data and relay this information instantaneously to control centers, facilitating informed decision-making and swift responses to dynamic wind conditions or equipment anomalies.

Complementing SCADA, IoT connectivity integrates turbines into a broader digital ecosystem, enabling enhanced data analytics and communication technologies that propel control systems beyond isolated, reactive controllers. Key components of this integration include:

- Real-Time Monitoring: IoT sensors transmit high-frequency data over wireless or wired networks, allowing for continuous tracking of turbine health and environmental factors. This immediacy aids in early fault detection and performance optimization.

- Advanced Data Analytics: Leveraging cloud computing and machine learning, accumulated SCADA-IoT data are analyzed to identify hidden patterns, predict failures, and fine-tune control parameters for improved efficiency.

- Smart Grid Communication: Wind turbines connected to smart grids exchange information with grid operators to provide ancillary services such as frequency regulation and voltage support. This two-way communication enhances grid stability while optimizing turbine output based on grid demands.

Together, SCADA and IoT form the backbone of intelligent wind turbine control architectures that enable real-time adaptive control, predictive maintenance, and coordinated grid interaction. This integration not only reduces operational costs but also maximizes energy harvest and turbine lifespan, making it a cornerstone innovation in contemporary renewable energy systems. Understanding these interconnected technologies is vital for engineers seeking to design, operate, or optimize wind turbines within the increasingly digitized energy landscape.

Image courtesy of Jakub Zerdzicki

Multi-Turbine Control and Wind Farm Optimization: Coordinated Approaches for Maximizing Output and Minimizing Wake Losses

While individual wind turbine control systems focus on optimizing single units, multi-turbine control and wind farm optimization represent the next frontier in renewable energy innovation. In large-scale wind farms, turbines interact aerodynamically, producing wake effects—turbulent wind patterns downstream of a turbine—that reduce wind speed and increase turbulence for neighboring units. These wake interactions lead to significant efficiency losses, heightened mechanical loads, and uneven wear across turbines if not properly managed.

Coordinated control approaches address these challenges by optimizing the collective operation of multiple turbines simultaneously rather than treating each turbine in isolation. Advanced wind farm control systems use centralized or distributed algorithms that dynamically adjust individual turbine settings—such as blade pitch, yaw angles, and generator torque—to minimize wake impact and maximize aggregated power output across the entire farm. Key benefits include:

- Wake Steering Control: Intentionally yawing upstream turbines slightly out of the wind flow redirects wakes away from downstream turbines, improving overall wind capture efficiency at the farm level.

- Optimal Setpoint Coordination: Using predictive models and real-time data, control systems assign dynamic operating points to each turbine that balance maximum energy output with mechanical load mitigation.

- Load Harmonization: Coordinated control smooths power fluctuations across the farm, reducing grid integration challenges and improving reliability.

- Energy Maximization under Constraints: By considering wake effects, turbine de-rating for noise or grid requirements, and environmental factors, wind farm controllers optimize energy production subject to operational constraints.

Implementing multi-turbine optimization relies heavily on advanced computational models, model predictive control (MPC) extensions for farms, and real-time sensor data integration. These systems leverage wind farm SCADA networks and IoT frameworks to continuously evaluate wind conditions, turbine interactions, and grid demands, enabling proactive and adaptive control decisions that transcend single turbine limitations.

Consequently, wind farm optimization not only boosts total energy yield by up to 5-15% compared to independent turbine control but also extends equipment lifespan by reducing fatigue loads induced by turbulent wakes. This coordinated, system-wide control paradigm is essential as wind farms expand in size and complexity, making it a cornerstone innovation for maximizing renewable energy production and grid stability in the era of large-scale wind power deployment.

Image courtesy of Eclipse Chasers

Emerging Technologies and Research Trends in Wind Turbine Control Systems

The future of wind turbine control is rapidly evolving through emerging technologies that leverage artificial intelligence, digital simulation, and hybrid system integration to push the boundaries of turbine efficiency and reliability. Among the most transformative trends are AI-driven control algorithms, digital twins, and hybrid energy system coordination, which collectively enable smarter, more predictive, and resilient wind power generation.

AI-Driven Controls: Smarter, Predictive, and Adaptive

Artificial intelligence is revolutionizing wind turbine control by enabling systems that learn from vast datasets and adapt dynamically to complex wind patterns and mechanical behaviors. Machine learning models, including deep neural networks and reinforcement learning, are increasingly employed to optimize blade pitch, torque, and yaw with higher precision than traditional model-based controllers. These AI-driven controls excel at:

- Predicting wind speed fluctuations and turbine responses ahead of time, offering proactive adjustments that maximize energy capture.

- Identifying subtle fault patterns early through anomaly detection algorithms, reducing downtime and maintenance costs.

- Coordinating multi-turbine operations within farms by learning optimal wake steering configurations under varying environmental conditions.

By integrating AI, control systems evolve from reactive to anticipatory, boosting both power efficiency and structural longevity in challenging wind regimes.

Digital Twins: Real-Time Virtual Mirrors of Turbine Systems

Digital twin technology creates high-fidelity virtual replicas of physical wind turbines, encompassing aerodynamic, mechanical, and electrical components. These real-time simulations enable in-depth performance analysis, predictive maintenance, and control optimization without disrupting actual turbine operation. Key advantages include:

- Continuous validation of control strategies in a risk-free virtual environment.

- Enhanced fault diagnosis by comparing expected and actual turbine behavior.

- Tailored design of control actions that account for turbine aging and site-specific conditions.

Digital twins bridge the gap between theoretical models and field realities, empowering engineers to fine-tune controls with unprecedented accuracy and speed.

Hybrid Energy System Integration: Coordinated Control for Renewable Synergy

As the energy landscape diversifies, integrating wind turbines with solar photovoltaic (PV) arrays, energy storage systems, and grid-responsive loads is gaining traction. Advanced control frameworks now manage wind turbines not in isolation but as part of hybrid renewable platforms, enhancing overall system flexibility and resilience. This integration involves:

- Synchronized control algorithms that balance power output among wind, solar, and batteries to mitigate intermittency and maintain grid stability.

- Real-time forecasting and adaptive dispatch to optimize renewable energy contributions in response to demand fluctuations.

- Hierarchical control architectures that coordinate distributed energy resources at microgrid or utility scale.

Hybrid system integration leverages the complementary characteristics of renewables, boosting total energy yield and enabling more reliable, clean power delivery.

Ongoing research continues to refine these technologies, aiming to develop autonomous, self-optimizing wind turbine control systems that harness AI, digital modeling, and smart grid interaction. These innovations promise to dramatically increase turbine efficiency, reduce operational costs, and accelerate the global transition toward sustainable energy solutions.

Image courtesy of Aleksey Kuprikov

Practical Challenges and Implementation Considerations in Advanced Wind Turbine Control Systems

Deploying advanced control systems for wind turbines in real-world environments presents several practical challenges that engineers and operators must carefully address to ensure system effectiveness, reliability, and cost-efficiency. While innovations like model predictive control, AI-driven algorithms, and real-time SCADA-IoT integration offer remarkable performance benefits, their successful implementation involves navigating issues related to sensor noise, computational constraints, and thorough cost-benefit analysis.

Sensor Noise and Data Reliability

Wind turbine control systems rely heavily on accurate sensor measurements to provide inputs such as wind speed, blade pitch angles, rotor speed, and vibration levels. However, sensor noise, signal drift, and environmental interference can corrupt data quality, leading to suboptimal or even erroneous control decisions. For example, ultrasonic anemometers and strain gauges are susceptible to measurement inaccuracies caused by turbulence, icing, or electromagnetic disturbances.

Effective control implementation requires robust signal filtering and fault-tolerant estimation techniques, such as Kalman filters or adaptive observers, to extract reliable state information despite noisy inputs. Redundant sensors and sensor fusion strategies can further enhance data integrity, but add complexity and cost. Thus, balancing sensor precision and robustness against cost and maintenance overhead is critical in practical systems.

Computational Constraints and Real-Time Processing

Advanced algorithms, particularly those involving model predictive control (MPC) and AI-based methods, demand substantial computational power to solve optimization problems or neural network inference within tight control cycle deadlines—often in the order of milliseconds to seconds. Wind turbines operate in rapidly changing environments where latency can degrade control quality and increase mechanical wear.

Implementers must carefully select hardware platforms (e.g., DSPs, FPGAs, or edge computing units) capable of meeting these computational demands without excessive power consumption or cost. Algorithmic simplifications, such as employing linearized models or approximate solvers, are common trade-offs to reduce processing load while maintaining acceptable performance. Additionally, ensuring software reliability and cybersecurity in embedded control systems is paramount to prevent failures or malicious interference.

Cost-Benefit Analysis and Economic Viability

Although advanced control systems can significantly improve energy capture, reduce mechanical stress, and extend turbine lifespan, their adoption must be justified by a thorough cost-benefit analysis. This entails factoring in:

- Initial investment costs related to sensors, actuators, computational hardware, and software development.

- Integration and commissioning efforts, including personnel training, calibration, and system validation.

- Maintenance and operational costs, which may increase due to more complex control architectures or additional sensor upkeep.

- Expected gains in energy production, reduced downtime, and prolongation of component life.

- Grid compliance and incentives, such as the ability to provide ancillary services or meet regulatory standards for power quality.

Stakeholders often weigh these factors against the turbine's operational environment, size, and expected lifetime. For instance, offshore wind farms with high maintenance costs and harsher conditions stand to benefit more from fault-tolerant, adaptive controls despite increased upfront expenses, compared to smaller, onshore turbines in moderate climates.

In summary, the practical deployment of advanced wind turbine control systems involves a delicate balance between technological sophistication and real-world constraints. Addressing sensor inaccuracies, computational limitations, and performing rigorous economic evaluations are essential steps to unlock the full potential of these innovative controls while ensuring reliability and scalability across diverse wind energy projects.

Image courtesy of Ludovic Delot

Future Outlook and Impact on Renewable Energy

Advances in wind turbine control systems are pivotal in shaping the future growth, reliability, and integration of wind power within the global renewable energy mix. As cutting-edge control algorithms become more adaptive, intelligent, and predictive, they enable turbines to maximize energy capture while minimizing mechanical wear, operational costs, and downtime. This increased efficiency directly translates into higher capacity factors and more cost-competitive wind energy, accelerating its role as a cornerstone of sustainable power generation worldwide.

Looking ahead, several key impacts highlight the strategic importance of advanced turbine control systems:

-

Enhanced Grid Stability and Integration: Modern control technologies empower turbines to provide active grid support services such as frequency regulation, voltage control, and synthetic inertia. By dynamically adjusting power output in response to grid conditions, turbines contribute to a more stable and resilient electrical grid, essential for managing high shares of variable renewables.

-

Scalability of Offshore and Large-Scale Wind Farms: As wind farms grow in size and complexity—especially offshore installations—advanced control systems enable coordinated multi-turbine management and wake mitigation strategies. This improves overall farm efficiency, reduces maintenance costs, and extends asset lifetimes, making large projects economically viable and sustainable.

-

Acceleration of Renewable Energy Adoption: Improved reliability and performance through sophisticated control reduce barriers for integrating wind energy into diverse markets, including remote microgrids and hybrid renewable platforms. This fosters broader access to clean energy and supports global decarbonization goals.

-

Enabling Autonomous and Smart Turbines: The convergence of AI, digital twins, and real-time IoT integration is driving the development of self-optimizing turbines that continuously learn and adapt without human intervention. These intelligent systems will enhance fault tolerance, predictive maintenance, and operational optimization at unprecedented levels.

In conclusion, the evolution of wind turbine control systems is not just a technological upgrade; it is a fundamental enabler for wind power’s scalable, reliable, and cost-effective contribution to the global energy transition. For electrical engineers and renewable energy advocates alike, understanding and advancing these control innovations is essential for unlocking the full potential of wind energy as a clean, resilient, and sustainable power source for decades to come.

Image courtesy of Patrick